Jet Engine Inlet Covers

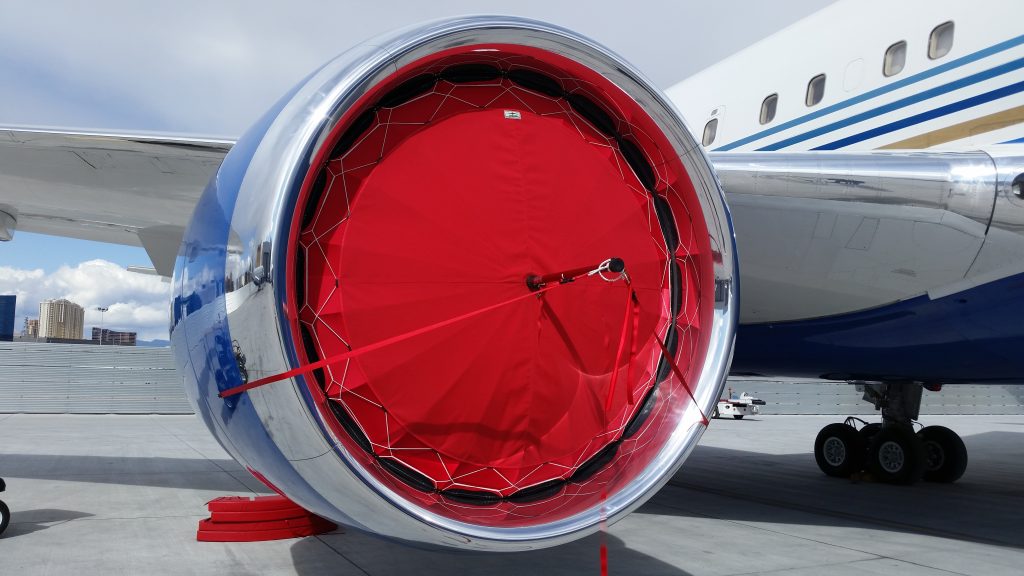

Jet \ Brella Inc. offers jet engine inlet cover solutions to protect your jet aircraft from Foreign Object Damage (FOD) and severe weathering. We also offer many custom colors, logo and design features for our private jet inlet covers. Jet Brella are ‘the inlet covers pilots love to use’.

Select Your Aircraft

- Bombardier Challenger 300

- Bombardier Challenger 350

- Bombardier Challenger 600

- Bombardier Challenger 601

- Bombardier Challenger 604

- Bombardier Challenger 605

- Bombardier Challenger CRJ

- Bombardier Global 5000

- Bombardier Global 6000

- Bombardier Global Express BD-700

- Bombardier Learjet 31

- Bombardier Learjet 35

- Bombardier Learjet 45

- Bombardier Learjet 55

- Bombardier Learjet 60

Custom Jet engine covers can come in different colors with custom logo designs and N tail numbers which can be embroidered on the covers to your specifications. Each Jet \ Brella inlet cover is made with durable and soft material to prevent cowl damage and worn parts. Inlet covers have venting mesh that allows breath-ability for the engine to prevent humidity corrosion and stops Turbofan engines from spinning under wind load.

INLET COVER INSTALL

Jet Engine FOD Damage Protection

Parked aircraft with exposed jet engines to snow, ice, sand, debris, nesting birds, and foreign objects can cause severe damage to expensive jet turbine engines if they are not properly protected. Ice buildup could fly into the jet engine striking the intake lip/bullet/guide vanes, etc., shattering into smaller pieces as it passes into the fan section, creating the soft FOD damage. Prevent mechanics from leaving loose nuts and bolts around the jet engine cowl with a protective cover. Speed up your preflight by keeping ice and snow buildup out of your jet engine cowl during snowstorms. Our Jet \Brella products will also protect your jet aircraft from corrosion that is primarily caused by exposure to humid environments. Jet Engine FOD Damage Protection is also an important part of the FAA Foreign Object Debris program. Our innovative jet engine inlet covers are ready to be shipped to protect your jet aircraft.

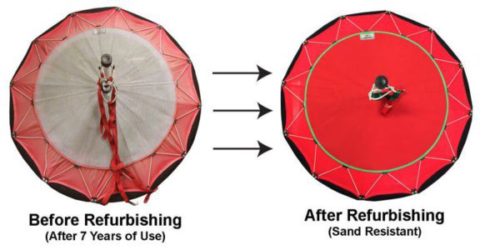

Inlet Cover Refurbishing

Continuous exposure to high winds, extreme temperatures, and the outdoor elements, the potential impacts can lead to erosion and structural fatigue, compromising an Inlet Cover’s ability to provide adequate protection over time. Refurbishing jet engine inlet covers involves inspecting the framework, cleaning and lubricating various parts, and replacing/upgrading worn or fatigued items as needed to enhance efficiency and protect against harsh conditions.